News Filter

Date

-

2011

-

2012

-

2013

-

2014

-

2015

-

2016

-

2017

-

2018

-

2019

-

2020

-

2022

News

What gives the Arbor ElectroGen 45 the edge?

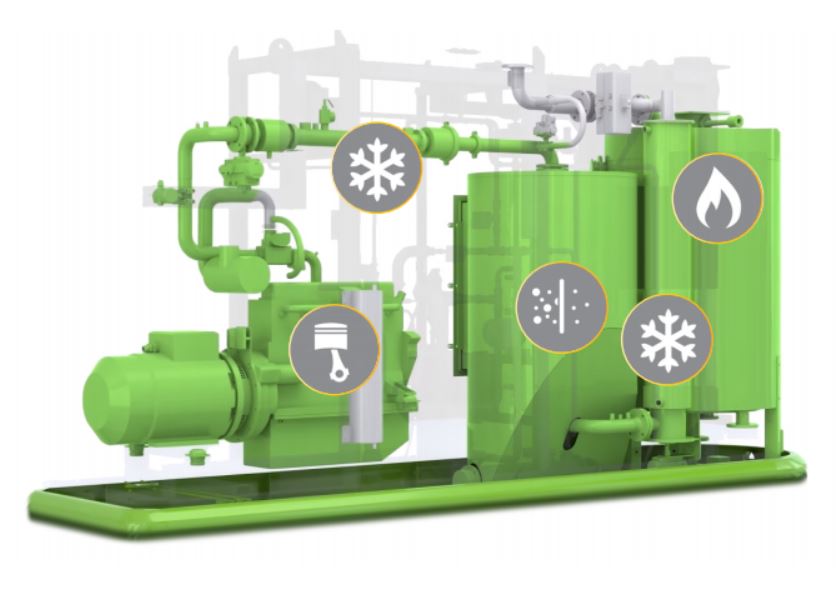

The Arbor ElectroGen 45 uses less fuel to produce more energy than any other biomass CHP plant currently available. Couple this with a less frequent maintenance schedule allowing more time for energy generation and it is no wonder farmers and landowners are looking no further than the Arbor ElectroGen 45.

The intelligent design of the gasifier within the Arbor ElectroGen 45 plant is what makes it all possible and why the Arbor unit can offer unrivalled returns. This is how it does it:

Temperature management

Most gasifiers suffer from ‘cool spots’ and therefore struggle to reach the very high temperatures required to reach gasification. This is due to only cool air being fed into the gasifier as well as the fuel becoming a clogged mass in the centre and restricting airflow. The Arbor unit is built using high grade insulating steel and extra insulation. The plant requires a large woodchip which allows for airflow between the fuel. Air is pre-heated before it enters the gasifier to raise the temperature and an additional air inlet feeds the pre-heated air into the centre of the gasifier resulting in an even temperature throughout the gasification chamber. For these reasons the Arbor ElectroGen produces a syn-gas with a higher calorie value making it the most fuel efficient biomass CHP plant available.

Zero Tar

Tar has always been an issue with gasification systems, however the Arbor ElectroGen has overcome this problem in two ways. Firstly the extremely high temperatures achieved in the gasifier create an environment where tar is unable to form. Secondly, whereas most other gasifiers extract syn-gas at the same point as where the ash is removed, the Arbor plant uses separate extraction points resulting in a much cleaner gas with fewer solid particles to be filtered out before being used as fuel for the engine.

Greater availability for generation

The Arbor gasifier uses a microwave sensor that doesn’t require regular maintenance and cannot jam like the equivalent mechanical devices used to manage the amount of fuel that is fed into the chamber. With fewer moving parts, virtually zero-tar production and no fuel clogging the Arbor gasifier requires significantly less service and maintenance. This is important as a gasifier can take several days to cool down before it is able to be serviced. It is for this reason we are able to account for 8,000 hours of up time per annum allowing our clients to generate more heat and power as well as greater subsidy returns.

You can find out more about the Arbor ElectroGen here or get a breakdown of typical annual returns and costs here. Alternatively, why not take advantage of our free site assessment service here.