Endurance E-Series Fixes & Upgrades

Since the liquidation of turbine manufacturer Endurance we have endeavoured to keep our client’s turbines generating. We have invested in over £1m of spares including generators, blade sets and gear boxes.

Our next step is to seek to improve weaknesses in the original Endurance designs and provide professionally engineered solutions to ensure the longevity of the machines across our entire fleet.

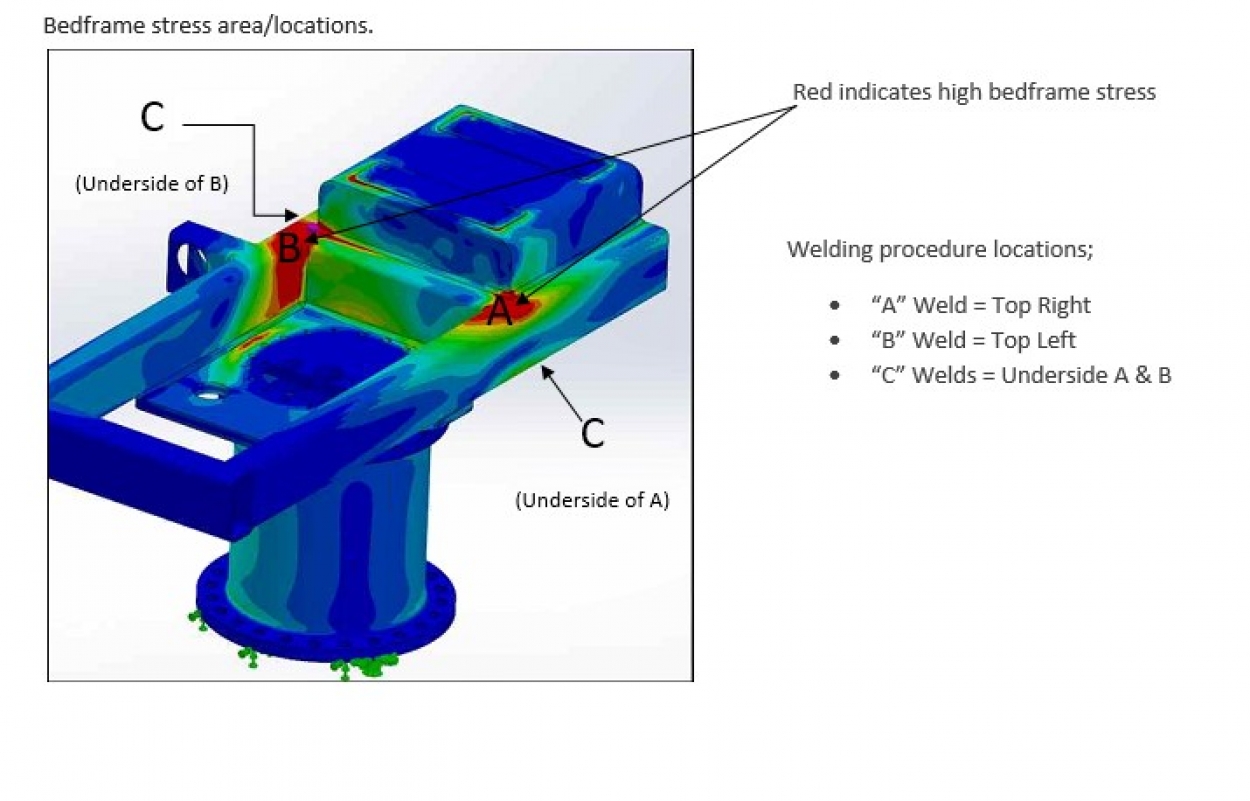

Bed plate repair and replacement

It has become apparent that some of the welds used in the original design of the Endurance E3120 bed plates are an area of weakness. Over time, normal operation of the wind turbine puts stress through the bed plate and cracks have appeared on some turbines, particularly those that are sited in high wind speed areas.

Working with specialist welding contractors we have designed a repair that is low cost and can be done up tower. For most instances of bed plate cracking this is the recommended solution for a medium term repair.

For the most severe cracks or a longer term solution, a redesigned, replacement bed plate has been developed for safe and reliable operation.

As a part of our recent acquisition of Britwind’s Endurance provisions, Earthmill Maintenance took over the manufacture of shafts and bed plates for Endurance E3120 turbines. This means we have been able to reduce the cost of a new bedframe for Earthmill Maintenance clients.

The new bed plate has been designed to ‘big-wind’ industry standards and improves hot-spot resilience by up to 3 times. The design has been built to withstand even the most testing operational loads including prolonged high winds and extreme turbulence.

In addition to this a new shaft has also been designed to eliminate the stresses caused by the keyway on the original design.

Main shaft Solution

The redesigned main shaft has been designed to strengthen critical stress areas which led to failures in a number of the original machines. The quality of steel used in its construction has also been improved.

The new design utilises more material in the critical stress area. The keyway has also been removed to eliminate stress concentration in this area. The new design has a higher load capacity in comparison with the original Endurance Wind Power design and an exponentially longer fatigue life than the original shaft.

It features a long life shaft using high grade steel, a new larger downwind pillow block bearing and housing, a new upwind pillow block bearing, a new tapered hub bushing and labyrinth seals and O-rings. There is no physical possibility of hub slip and risk of hub transferring torque via downwind taper bolts if became loose. The system is designed that the coupling methods (taper lock or locking plate) can carry the peak load. In normal operation, they share the torque. Furthermore, there is no risk of friction welding of the taper lock to hub.

-

Service & Maintenance

Earthmill Maintenance provide comprehensive service and maintenance packages to keep your technology running at optimum efficiency.

About Service Packages -

Condition Monitoring

The most important choice you can make to protect your turbine by identifying faults at an early stage to avoid major incidents

Find out more -

Buy/Sell Turbines

Flexible options to cash in on your existing turbine by selling it to our partners or begin the process to purchase and install a new one

Buy/Sell Options