News Filter

Date

-

2011

-

2012

-

2013

-

2014

-

2015

-

2016

-

2017

-

2018

-

2019

-

2020

-

2022

News

Our Essential Guide to LAMMA 2016

LAMMA is almost here! We’ve put together a handy show guide for you with all the essential information, hints and tips you need to know:

Do you need to register and how much does it cost?

You don’t need to register to attend LAMMA and it costs nothing to attend! The show takes place at the East of England Showground, Peterborough.

What are the opening hours and where can you park?

There is plenty of parking available on-site and it’s completely free to use. The show takes place on Wednesday 20th (7.30am – 5.00pm) and Thursday 21st (7.30am – 4.30pm). On both days the carpark opens early to you can beat the traffic and enjoy an early bird breakfast.

Grab breakfast when you arrive

Early bird breakfasts are served between 6.30am and 8.00am. Not a good time for you? Fret not. After 8.00am you can grab a Lamma All-day Breakfast instead. Perfect!

Pick up a show guide at the gate

LAMMA is a big event, with a huge amount to see and take part in. Don’t forget to collect your show guide at the gate when you go in.

Win a brand new Blue Power New Holland tractor

Enter Hew Holland’s free prize draw for a chance to win a new model T7.225 Blue Power Tractor. The T7.225 has a weight ratio of 28kg/hp and comes with a full integrated three-point hitch, EPM available in reverse, exhaust brake and Auto Command transmission. An ideal machine for a range of tasks from tillaging and spraying to transport. Enter the prize draw here or see New Holland on the day. Someone has to win it!

Is there a cash point on-site?

There are two cash points on site. Check out your show guide for the exact locations.

Is there WiFi?

There certainly is. Refer to your show guide for the visitor WiFi zones.

And finally, don’t miss your seat on a CHP Round Table session

We’re going to be running several short CHP Round Table sessions where you can join in the discussion, get all your questions about biomass CHP answered and find out how a compact plant can generate between £38,000 and £100,000 of savings and revenue per year. Sessions are at 11.00am, 1.00pm and 3.00pm. Give us a shout on 01937 581011 to book your seat at the table.

Not sure you can make it to a session? No problem, drop in and see us on Stand 870, Hall 8 at any time – our team will be happy to talk to you.

For more information about LAMMA you can visit the official LAMMA website here, and for more information about biomass CHP you can read more here.

News Filter

Date

-

2011

-

2012

-

2013

-

2014

-

2015

-

2016

-

2017

-

2018

-

2019

-

2020

-

2022

News

Find out how much could you earn from CHP

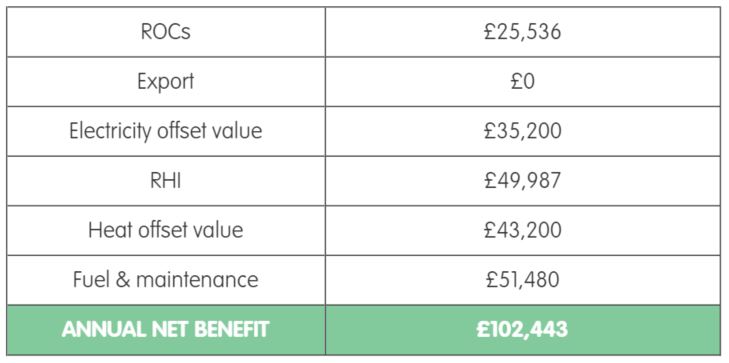

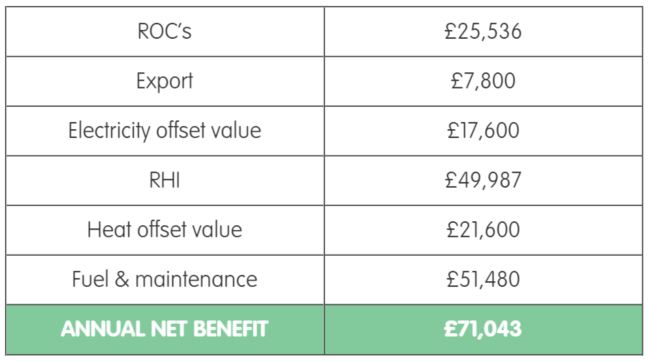

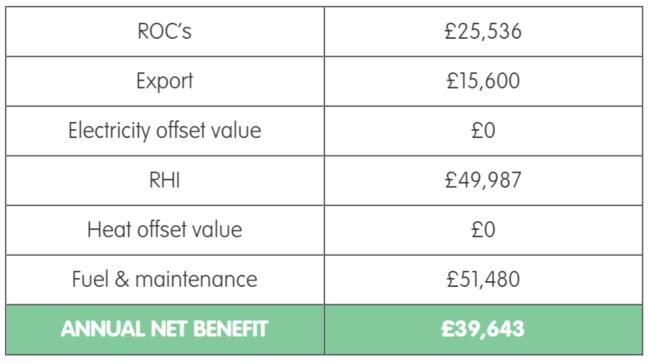

Biomass CHP is worth an annual net financial benefit of between £40,000 and £102,000 (per plant), depending on whether your business has a high, medium or low requirement for heat and power. The technology is efficient enough to be viable for any level of energy user. Please see the charts below to see which bracket you might fall into and an estimate of how much a single combined CHP plant could be worth to your business every year.

Please click on any of the charts below to enlarge:

High Energy User

Medium Energy User

Low Energy User

*Where there is surplus heat from the plant, this can be used to generate further additional revenue through a new use or can be used to reduce fuel costs for the plant by drying the woodchips on-site.

If you would like to learn more about biomass CHP or have the value of CHP to your business assessed then please contact us on 01937 581011 or request a free desktop assessment online.

News Filter

Date

-

2011

-

2012

-

2013

-

2014

-

2015

-

2016

-

2017

-

2018

-

2019

-

2020

-

2022

News

Why the ArborElectroGen is our biomass CHP system of choice

Earthmill have a reputation for only supplying the best, the most efficient, and the most reliable technology. The ArborElectroGen 45 is an advanced gasification biomass CHP system and by far and away the best CHP solution available. These are some of the reasons this system made it through our rigorous testing process:

Virtually tar free

The ArborElectroGen is the only CHP system that has achieved a method of gasification which is virtually tar free. The unique, patented system removes any tar components before they can form as a sticky residue downstream from the gasifier. Consequently the messy removal and handling of tar is not required with the system thanks to the AborElectroGen’s automated system.

As a failsafe mechanism, if any conditions are sensed that would impact the operation (e.g. fuel too wet) then the system will automatically lock down the gas lines with pneumatic valves preventing any poor quality gas ingress into the system.

If not removed, tar can collect in piping, forcing frequent shutdowns and costly maintenance. Circumventing the issue of tar management serves as great advantage over comparable units, maintaining system health and maximising generation time.

Naturally aspirated engine

Operating for 24 hours a day for extended periods will put any engine to the test. Whereas most CHP plants use turbo charged engines, the ArborElectroGen uses an 8.4L naturally aspirated engine which ticks over at just 1500rpm putting it under less strain in comparison to other systems.

The engine was developed specifically for use in the ArborElectroGen by Finnish CHP & gasification specialists Volter who worked closely with agricultural engine makers Agco.

Whilst a complete engine rebuild every 3 years is included as a part of the routine service and maintenance schedule, Volter is testing the first system to destruction in the Arctic Circle in the North of Finland. The system is still going strong after more than 7 years in operation with no major maintenance other than basic servicing.

No moving parts

No moving parts

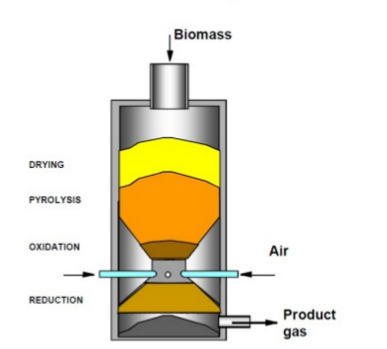

The ArborElectroGen uses a downdraft gasifier. Downdraft gasifiers have been developed to convert wood fuelled gas and have proven to be the most successful design for power generation.

The unique, patented design incorporates no moving parts, reducing the number of times it needs to be serviced. Gasifiers take around 3 days to cool down in order to be serviced so the fewer times this needs to happen means more availability for the plant to be generating and earning money.

5 Year gasifier warranty

The manufacturer are so confident in the reliability of the gasifier that they offer a 5 year warranty on it!

93% lower carbon emissions than equivalent gas-fired CHP systems

The system produces little to no visible smoke plume from its flue, virtually no particulates, virtually zero Nitrogen Oxide, and has Carbon Dioxide emission levels that are 93% lower than that of an equivalent natural gas-fired CHP system. This means they can even be used in smoke control areas.

If you’d like to find out more about CHP and it’s potential feasibility for your business then you can read more here or get an estimate of your prospective annual returns here. Alternatively you can contact us on 01937 581011 or request a free site assessment online.

News Filter

Date

-

2011

-

2012

-

2013

-

2014

-

2015

-

2016

-

2017

-

2018

-

2019

-

2020

-

2022

News

DECC announcements turn Earthmill’s focus to CHP

Since gaining power with a surprising majority vote at the general election in May, the Conservative Government has been swiftly following up with the promises made in the party’s manifesto which impacts on wind turbine applications.

In recent months the Government’s Department for Energy and Climate Change (DECC) have announced changes to planning rules for all wind turbines and abandoned pre-accreditation. The most recent announcement follows DECC’s review of the Feed-in Tariff or FIT scheme.

The FIT review proposes to slash subsidies available for farm scale wind from January 2016 making many projects financially unviable. Earthmill managing director, Steve Milner responded to the announcement “we always knew that a reduction in the Feed-In Tariff was imminent however the FIT review proposes sharper cuts to the tariff than we had anticipated. We are still very much dedicated to installing wind turbines however the cuts mean that going forward only sites with a very high energy requirement will make sense financially.”

However not all renewable technology has been affected by the proposed cuts. Wood fueled combined heat and power plants generate heat and electricity by gasifying wood chip. The systems rely on the Renewable Heat Incentive (RHI) and Renewable Obligations (ROCs) to support farms and businesses in reducing their carbon footprints. So far these subsidies have not come under Government scrutiny meaning that the Arbor ElectroGen 45 CHP plant that Earthmill supply has a payback period of less than 5 years.

Milner added, “CHP is a relatively untapped technology and therefore the supporting tariffs are still very high. Farms and businesses with a large heat demand can now get paid to generate their own electricity and heat and have the added benefit of energy security for the future. Pig and poultry farmers with a high heat requirement stand to benefit the most from this kind of technology but it also makes a lot of sense for application on industrial sites and large businesses. The Arbor 45 CHP unit was the first OFGEM accredited CHP plant and offers the best returns available. Earthmill have formally agreed with Arbor Heat and Power to exclusively supply it to Yorkshire, Cheshire and North Wales.”

Earthmill are currently offering free online site assessments to anyone who thinks that they may be able to benefit from CHP.

News Filter

Date

-

2011

-

2012

-

2013

-

2014

-

2015

-

2016

-

2017

-

2018

-

2019

-

2020

-

2022

News

The 4 most important things you need to know about CHP

Combined Heat & Power (CHP) is one of the most efficient sustainable energy technologies available and absolutely ideal for farms and agriculture. CHP is designed to produce both heat and electricity simultaneously, and can add considerable value to a business. This is what you need to know:

1. CHP is an easy project to get off the ground

CHP doesn’t require a formal planning application and doesn’t rely on you having a lot of open space, the correct land topography or a suitable distance from unnatural features such as neighbouring properties. The flue of a CHP stands under one meter and the emissions are so clean that a plant can even be situated in restricted areas such as inside listed buildings, city centres and conservation areas.

2. The value of CHP is multifaceted

Combined Heat & Power does exactly what it says on the tin: it generates both heat and power at the same time. The heating aspect of a CHP plant is set up to go where it will be most valuable during installation, making it a particularly useful option for businesses which need to dry raw materials, sterilize products or heat large spaces. The heat from the unit can be directed to as many commercial destinations as desired, such as dryers, dairies, workshops, holiday cottages, greenhouses etc.

The electricity generated by the plant can either be routed to power your business directly with any extra being sold back to the Grid (at export rate) or the system can be set up to sell all generated energy back to the National Grid.

CHP also qualifies for ROCs and RHI, both of which are government backed schemes put in place to incentivise businesses to generate their own heat and power. Put together, the first hand value of CHP in reduction of heat and power bills plus incentivised income allows for a rapid payback period (typically under five years) and an excellent secure income.

3. CHP requires a smaller Grid connection

With Grid capacity filling up rapidly on a national scale, many applicants for larger scale renewable and sustainable energy projects are finding that they’ve arrived too late and there isn’t enough Grid capacity left locally to support their project.

However, CHP plants only require a very modest Grid connection which could allow landowners in Grid-tied areas to bring a sustainable energy project to reality. Despite only requiring a 40kW connection, a CHP plant generates energy on a constant basis and so is capable of generating 320,000kWh of electricity and 720,000kWh of heat per year.

4. CHP plants are sustainable and low in carbon emissions

A Combined Heat & Power plant is a self-contained system fuelled by sustainably sourced wood chips. A local supplier delivers sustainably sourced wood chips at routine intervals and feeds them straight into the plant’s fuel store, from where an auger will automatically feed the wood chips into the plant. Generating heat and power in this way allows you to significantly reduce the carbon footprint of your business.

Using correctly sourced wood chips produces 93% less CO2 than equivalent gas-powered systems. There is little to no visible smoke from the flue and the system produces virtually zero nitrogen oxides.*

Want to find out more? Our team can answer your questions, provide a free desktop feasibility assessment and see if your site is suitable for CHP. Call us on 01937 501011 or request an assessment online.

*These figures are based on the CHP technology Earthmill supplies and we can’t guarantee that they accurately represent other commercially available CHP technologies.

News Filter

Date

-

2011

-

2012

-

2013

-

2014

-

2015

-

2016

-

2017

-

2018

-

2019

-

2020

-

2022

News

Earthmill the first to install the Endurance Wind Power X35Q 180kW turbine.

Earthmill are celebrating after becoming the world’s first installer of the new Endurance Wind Power X35Q turbine.

Based on a tried and tested Norwin design, the X35Q’s increased blade length and low rotor speed make the turbine well suited for areas with lower wind speeds and smaller sites. The increased swept area allows for high efficiency and the slower turning blades reduce noise. The ‘Q’ stands for quiet!

“The new model is an exciting edition to our turbine range,” commented Mark Woodward, Earthmill’s Commercial Director. “Being able to use a low voltage connection and removing the need for ground mounted transformers, the X35Q can reduce the overall cost of grid connection making the numbers stack up even on sites with a lower wind speed.”

Andrew Pick, Yorkshire Farmer says: “We chose the X35Q as it is remarkably quiet. The 180kW generator made it possible to reduce our original grid quote for a larger connection from millions of pounds to something financially viable.”

The X35Q is the fifth model to be released in the Endurance Wind X – Series Turbines.

Visit our X35Q page or, alternatively, contact our team on 01937 581011 for more information and a free viability assessment.

News Filter

Date

-

2011

-

2012

-

2013

-

2014

-

2015

-

2016

-

2017

-

2018

-

2019

-

2020

-

2022

News

Earthmill launches Combined Heat & Power (CHP)

Earthmill is pleased to launch a brand new product: Combined Heat & Power (CHP).

Combined Heat & Power is a new solution to generating on-site sustainable energy. The system allows business owners to generate both heat and electricity, making CHP an ideal option for businesses with higher heating requirements, such as dairies.

“CHP is an exciting technology which will bring real benefits to landowners and farmers. This is the first sustainable energy technology to match the exceptional returns we first saw with wind generation,” says Earthmill MD Steve Milner.

He continues: “While Earthmill is still dedicated to supplying farm-scale wind turbines, CHP is a brilliant option that can be used either hand-in-hand with a turbine or as an alternative where a turbine isn’t viable or possible.”

News Filter

Date

-

2011

-

2012

-

2013

-

2014

-

2015

-

2016

-

2017

-

2018

-

2019

-

2020

-

2022

News

DECC announcement does not affect Farm Wind

Government’s changes to onshore wind subsidy:

Wind was in the news again last night, as always the media haven’t been clear to differentiate between farm scale wind projects under 1.5MW which utilise the FiTs scheme and the onshore wind farms that receive ROC’s

The announced changes are to “wind farms” receiving ROC’s and not FiTs which is being reviewed as planned later this summer.

The FiTs scheme is key to the success of farm scale wind and community projects which have been highlighted as an important part of the governments strategy to allow local communities to benefit from wind.

News Filter

Date

-

2011

-

2012

-

2013

-

2014

-

2015

-

2016

-

2017

-

2018

-

2019

-

2020

-

2022

News

Earthmill Online – Slick new website launched

Earthmill is delighted to announce the launch of our new redesigned website, earthmill.co.uk. The new look website was built, designed and populated by EWBD Marketing and PixelBuilders. This exciting collaboration has produced a striking, informative and user friendly site.

The new site design incorporates the new company branding and with a cleaner more updated design this website aims to significantly enhance the overall user experience. The new website showcases a number of new products and packages, as well as providing a comprehensive walkthrough of the entire turbine acquisition process, from planning right through the installation and maintenance.

Oliver Leake, Marketing Manager at Earthmill said “The new website is a great tool for anybody who wants to learn more about installing a turbine. Users can request a free site assessment in less than 30 seconds to see if they have a feasible site for a wind turbine.”

News Filter

Date

-

2011

-

2012

-

2013

-

2014

-

2015

-

2016

-

2017

-

2018

-

2019

-

2020

-

2022

News

Wetherby business gears up for Acorn Bike Ride

Mark Woodward, commercial director of Wetherby wind turbine business, Earthmill, and a team of eight colleagues saddled up to take part in the annual 100km Acorn bike ride on 9 May, raising more than £2,200 for the Acorn charity, which supports people with dementia and their carers in the Harrogate and Ripon area.

Mark said: “I’d done little or no training and my longest ever cycle ride had been a measly 30km jaunt, so I wasn’t exactly well prepared. In fact on the day itself I sailed through the first half of the ride, but then we turned back into what felt like a force 10 gale which didn’t give up for the next 50km and it became quite gruelling.”

Mark added: “My legs were killing me and we passed 18 nice pubs which my companions refused to let me stop in! At one point I even considered attending the open gardens in Newton-upon-Ouse just to give my legs a rest, and I knew things weren’t going all that well when a couple of pensioners on a tandem overtook me going up a hill.”

Nevertheless the Earthmill team battled on and completed the course. “It was well worth the pain to raise money for such a worthwhile cause. These days it seems most people’s lives have been touched in some way by dementia and sponsored events like the Acorn ride are a brilliant way for everyone to get involved in fundraising.”

This year 620 cyclists took part in the Acorn Bike Ride, raising around £35,000 for the charity.

Mark’s Just Giving page is still open for sponsorship at www.justgiving.com/Mark-Woodward4